Waste management

company

Engineering company

Hospital

Furnace maker

(incinerator, industrial furnace, APC)

Government

Licensing

Distributor

Agency

Export(ODA)

| Plant images |  |

|---|---|

| Ability | 5-10 ton/day |

| Location | small centralized facility |

| Target | infection industrial waste |

| Operator | 4 persons |

| Heat recovery | ○ |

| Advantage | Good economy from income and running costs. |

| Plant images |  |

|---|---|

| Ability | 50-500kg/day |

| Location | Hospital |

| Target | infection industrial waste |

| Operator | 1 person |

| Heat recovery | △ |

| Advantage | To detoxify infectious waste on site. |

| Plant images |  |  |

|---|---|---|

| Ability | 5-10 ton/day | 50-500kg/day |

| Location | small centralized facility | Hospital |

| Target | infection industrial waste | infection industrial waste |

| Operator | 4 persons | 1 person |

| Heat recovery | ○ | △ |

| Advantage | Good economy from income and running costs. | To detoxify infectious waste on site. |

KINSEI has the superior technology of the incinerator.

Medical waste has a risk of infection, the proper treatment is important.

Incineration is the most safe compared with autoclaving, disinfection, and melting.

Usual incinerators, the running cost is high, also generates environmental pollutants.

KINSEI incinerator, running cost is cheap, environmental pollutants also very small.

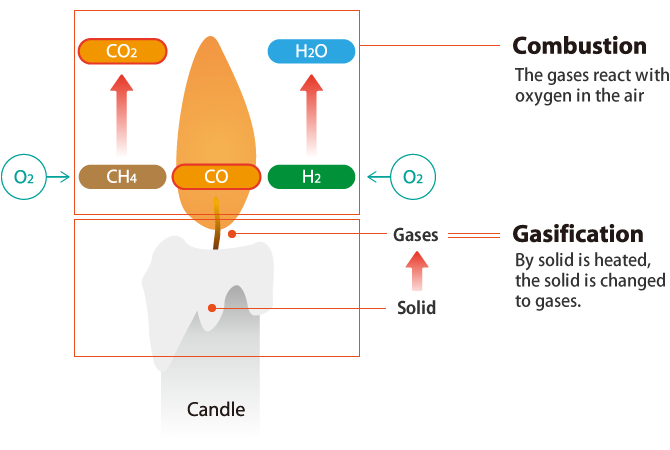

Gasification is chemical reaction.

Candle does not burn directly.

KINSEI technology "gasification"

is based on the principals of combustion reaction.

Gasification temperature prevents air from flowing back into the gasification furnace and combustion furnace. [patent]

The ideal gasification through structure and control.

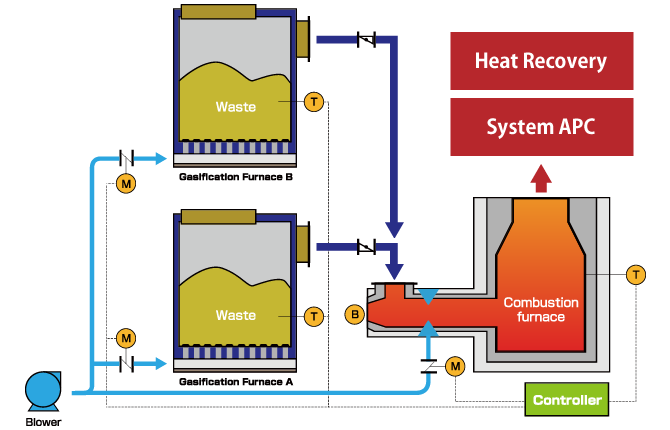

Kinsei gasification Combustion System is composed of two bach gasification furnaces and one combustion furnace.

The waste materials are charged in the gasification furnace A by the feeding system. And repeat several times, gasification furnace A is filled up to capacity.

After full charge, the gasification furnace A is ignited.

Gasification is proceed with keeping constant temperature and gas volume of the combustion furnace by automatic control system.

In the meantime, the waste materials are charged in the gasification B, and the gasification furnace B is filled to capacity.

And when the gasification of gasification furnace A is concluded, the gasification is switched from A to B, and A progress to next step " cooling".

After the temperature of A go down, the workers discharge the ash from A, and clean up the reactor.

This is one cycle of Kinsei gasification combustion System.

It is possible to continue operation according switching two gasification furnace alternately.

Takasaki City Excellent SME Award

February 18, 2019

Given to companies that have made achievements in promoting commerce and industry in Takasaki City.

Regional future leader

December 22, 2017

A company that has achieved results nationwide, can lead the local economy, and can be the core of growth.

Selected from about 2000 companies.

Autumn Medal The Order of the Rising Sun, Gold and Silver Rays

November 3, 2015

Prefectural government, local autonomy, social welfare, maternity, etc.